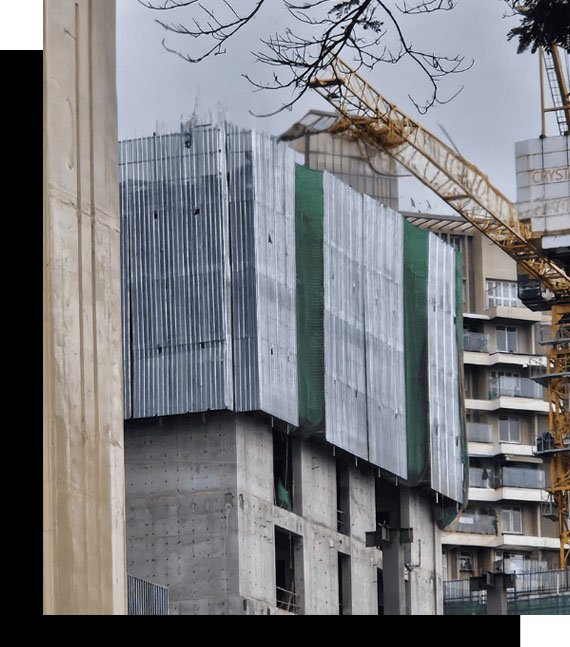

SB Safety Screen is wind-resistant and it comes with a metal perforated sheet, giving the site team a much better feeling of safety, and so it boosts their productivity.

Introducing the Peripheral Edge Protection Screen from SB Scaffolding India Pvt Ltd—a revolutionary solution designed to elevate safety, flexibility, and productivity on construction sites. This state-of-the-art protection screen provides comprehensive work floor enclosure, edge protection, and weather shielding, ensuring a secure and efficient work environment. Perfect for high-rise buildings and complex construction projects, our Protection Screen is engineered to meet the highest safety standards and adapt seamlessly to your evolving project needs.

SB Safety Screen is wind-resistant and it comes with a metal perforated sheet, giving the site team a much better feeling of safety, and so it boosts their productivity.

The perforated Sheet provides natural lighting, at all the enclosed work levels across the whole area of the enclosure.

Lightweight flexible system for easy installation, saves crane time, as complete assembled unit moves from one level to another.

Pre-assembly (ready-to-use at the site) options for restricted site conditions are available.

Training is provided for the on-site team, so it becomes easy for them to understand and operate the system.

Provides advertising space for Promotional Activity for your project.

System designed as per following relevant standards - Class-2 scaffold as per BS:1139 part-5 & Wind loads as per IS:875-part-3 (44 m/sec for Mumbai region)

|

Sr. No. |

Product Features |

Specifications |

|

1 |

Standard Panel Dimensions |

1.5 x 3.0 meters, 3.0 x 3.0 meters, or customized sizes to suit the building geometry. |

|

2 |

Working Platform Width |

600 mm, erection starts from 2nd level onwards. |

|

3 |

System Weight for one module |

0.75 Tons to 2 Tons, depending upon the number of levels to be covered by the Protection Screen. |

|

4 |

System shifting |

By Crane, it takes 4 to 6 min. for relocating the single unit. |

|

5 |

Transportation |

Suitable for standard transport |

|

6 |

Suitability |

Up to 200-meter height for various building shapes & perimeters. |

Safety is our top priority. The Protection Screen ensures your team and the site's well-being with a high level of security. The wind-resistant screen makes the team feel more secure, resulting in higher productivity.

Our Protection Screen is a lightweight and flexible system, making installation a breeze. It saves valuable crane time as the complete assembled unit can seamlessly move from one level to another, adapting to the evolving needs of your project.

For projects with restricted site conditions, we offer pre-assembly options. This means your Protection Screen arrives ready-to-use on-site, minimizing downtime and maximizing efficiency.

To ensure your on-site team operates the system with confidence, we provide comprehensive training. Understanding and using the Protection Screen becomes second nature, further enhancing safety and productivity.

Your project deserves recognition. The Protection Screen is not only safe, it serves as a promotional tool, making your project stand out with valuable advertising space.

The perforated sheet not only provides protection but also allows natural lighting to permeate all enclosed work levels across the entire enclosure area. Say goodbye to dimly lit workspaces and hello to improved visibility and comfort.

The Peripheral Edge Protection Screen is ideal for various construction projects, especially high-rise buildings. It is used for:

Ensuring a secure perimeter around the work floor.

Preventing falls and enhancing worker safety.

Protecting against adverse weather conditions, allowing uninterrupted work progress.

Extending beyond the slab edge to provide additional working space.

Utilizing the screen's surface for project promotion and branding.